Relapping tools

The purpose of a relap is to enable the tool to be used as new again, by creating a

new sharp cutting edge. Other

definitions found for the term relapping are such as re-sharpen, re-grind, repair,

re-polish, re-cut...

While a tool is used the cutting edge will wear due to several dynamics. At a

certain point, the cutting edge is

becoming too blunt or worn out for doing its cutting job. This is when you decide to

take out the diamond and sent it

for relap.

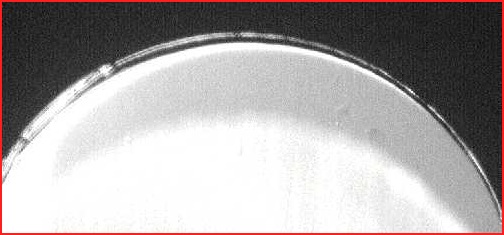

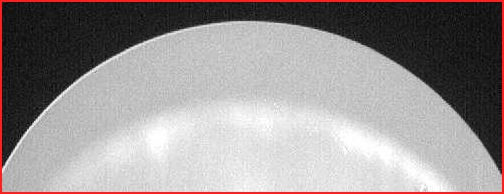

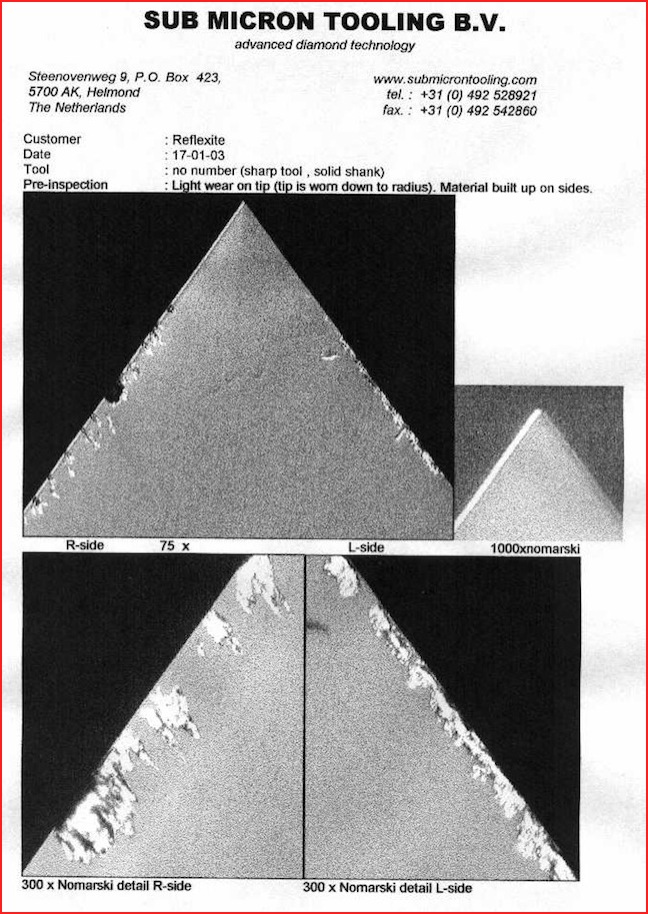

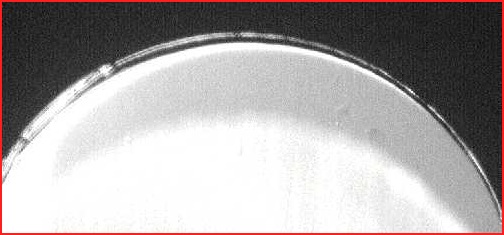

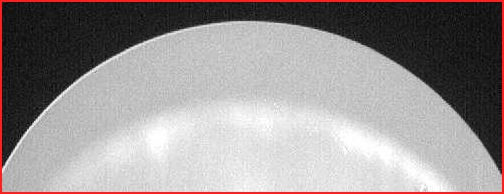

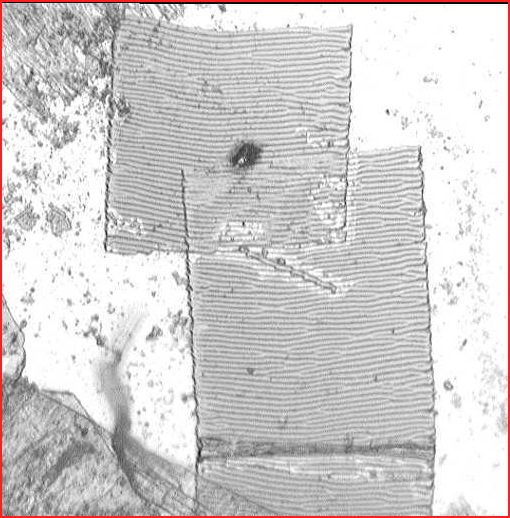

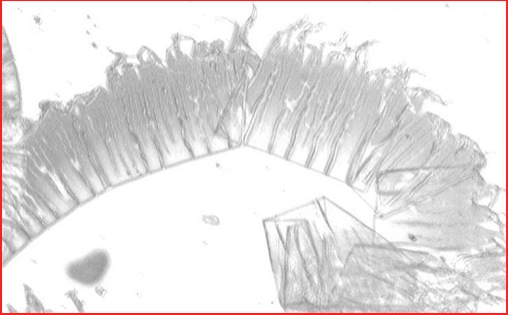

Example of a relap

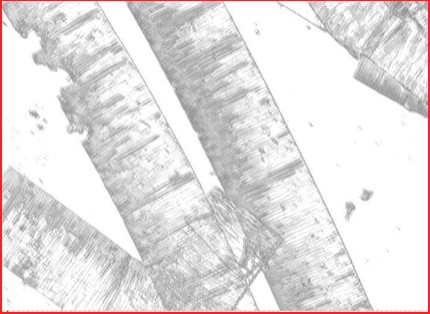

Shown is a synthetic radius diamond, used on a 2-axis cutting lathe. It has cut approx. 16,000 RGP lenses. Visible is a severe cutting edge and form wear nicely spread over the entire radius, which is mostly typical 2-axis use.

By grinding off diamond material from the table side, the wear will be disappeared on both table and clearance once enough is taken off. This means that a clean table and clearance shape have become the cutting edge. The wear-gallery is giving examples of wear on the clearance.

As a new cutting edge is formed, some tool parameters might have changed. For those

applications where the exact

properties need to be known, the radius size and the waviness will be measured. This

new data, including the amount of

diamond taken off and the wear detected, will be noted on the Tool Record. Also,

just like with new tools, a current

Measurement Certificate can be made of the relapped tool, displaying the waviness

characteristics more in detail.

When the tool is properly used, a relap can be done several times using the same

tool. The amount of relaps per tool

depends however on the application, the machine used, the material cut, the cutting

strategy, the environmental

conditions, the geometry of the tool, and even sometimes the operator involved.

On average, a tool used for roughing purposes can be relapped 20-50 times. A tool

used for finishing purposes can be

relapped 30-80 times. In combination with our Tool Management system, the usage can

be extended up to over 100 times.

Tool Management

Sub Micron Tooling is specialised in diamond tooling and the repair (relap) of

diamond tools. Due to the importance a

tool can have, as being part of a production process, the performance of the tool

can have great impact on the success

of the user. Hence, any optimalisation of a tool is recommendable and close relation

is needed with the user. Sub Micron

Tooling is a world-wide operating company based in the south of the Netherlands.

Yet, a good communication with the user

of a tool is needed in order to continue evaluating the performance of a tool and to

continue striving to optimise the

processes the tool is used for. For this, we developed "Tool Management®" in 1996, a

service that has some great

advantages over any conventional service.

To name some interesting benefits of Tool Management

Fast relax service

On a standard basis, tools will be relapped and shipped back within 48 hrs after receipt. This means that you will have fewer tools in circulation, thus less investments involved.

Consistent quality

All tools are inspected and measured before and after repair to guarantee that tools will work. All the important tool information such as radius size, waviness, wear patterns, cutting height, etc. will be updated after each relap and corresponded to you.

Longer tool life

Because we realise more relaps per tool, you will have to buy fewer new tools. All our new tools are designed for maximum diamond life.

Building up knowledge

As we analyse and inspect each tool on its wear, causes may be found and therewith

learning know-how. This will be

reported to you for each tool.

After the aforementioned benefits and promises, we would like to explain how we keep

them. Therefore we add in more

detail what "Tool Management" is about.

"Tool Management makes it possible to optimise the use of diamond tools".

By using diamond tools, wear and damage will develop. This wear and damage is related

to a great variety of factors,

such as the tool geometry, the lathe being used, the material cut, the product being

made, the cutting parameters

(speed, feed), the operator, environmental conditions, etc. etc. So, by looking at

the wear and damage we are able to

obtain information about the cutting processes at the customer and their quality

needs. By obtaining this information we

are gaining knowledge about the customer, from which the customer benefits. On base

of our knowledge on diamond tools in

general, applications, lathes, cutting strategies, customer related knowledge and

the quality needs of the individual

customers we can give advise, come up with solutions and improve processes.

The above approach, together with a fast relap service, maximum diamond life, tool

trace ability, state of the art

technology and very competing prices will give you, our customer, the possibility to

optimise the use of your diamond

tools.

In short, the steps are as follows:

- Customer ships tool(s) to SMT by post or forwarding agent.

- Tools are being received by SMT and generally inspected. The customer receives a confirmation that tools are received, an expected delivery time and estimated price.

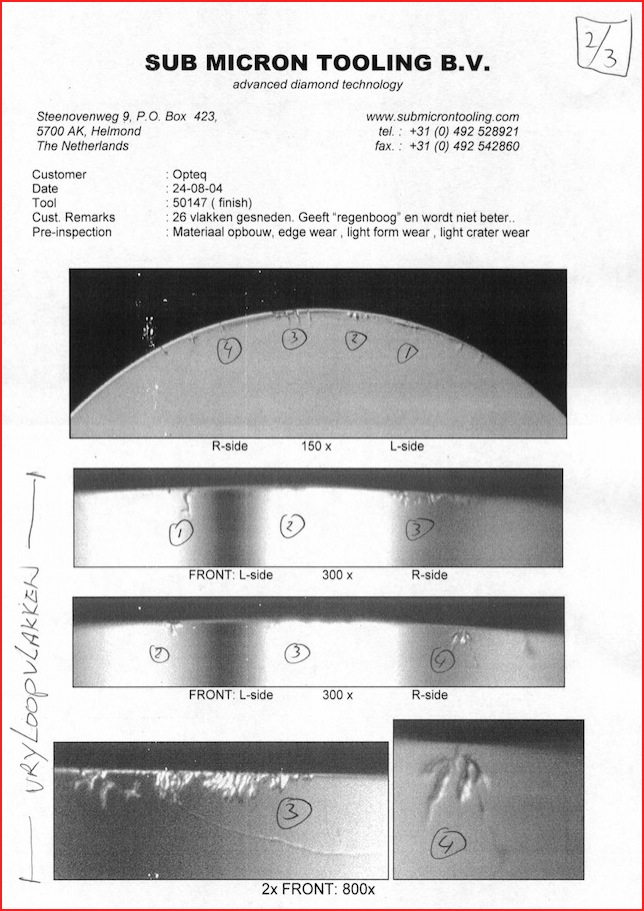

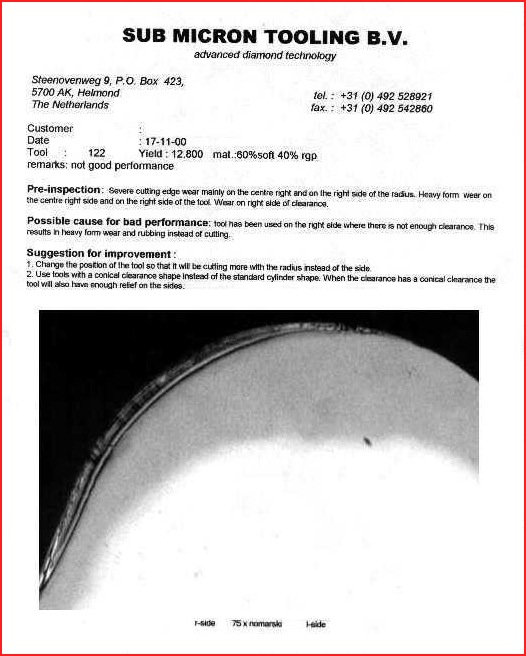

- Tools are individually inspected and the wear analysed. For each tool, a tool record is being made, and if possible and needed a pre-inspection report is being made. The waviness of the radius is being measured before the relap, as this may be an indication of the wear and the cutting process it is used for.

- On base of the pre-inspection and measurement, we decide how the tool will be relapped in order to take off a minimum of diamond height, obtain a maximum tool life and remove all wear and damage.

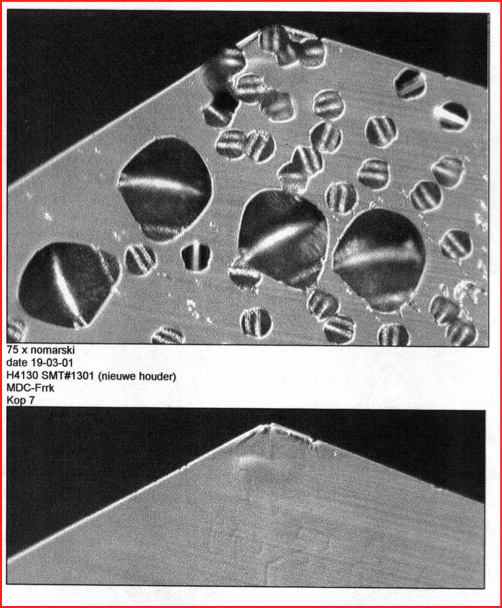

- The tool is relapped on specially designed relapping machines, which prevents stress in the diamond and lapping lines.

- After relap the tool is inspected and measured to make sure all wear and damage is removed.

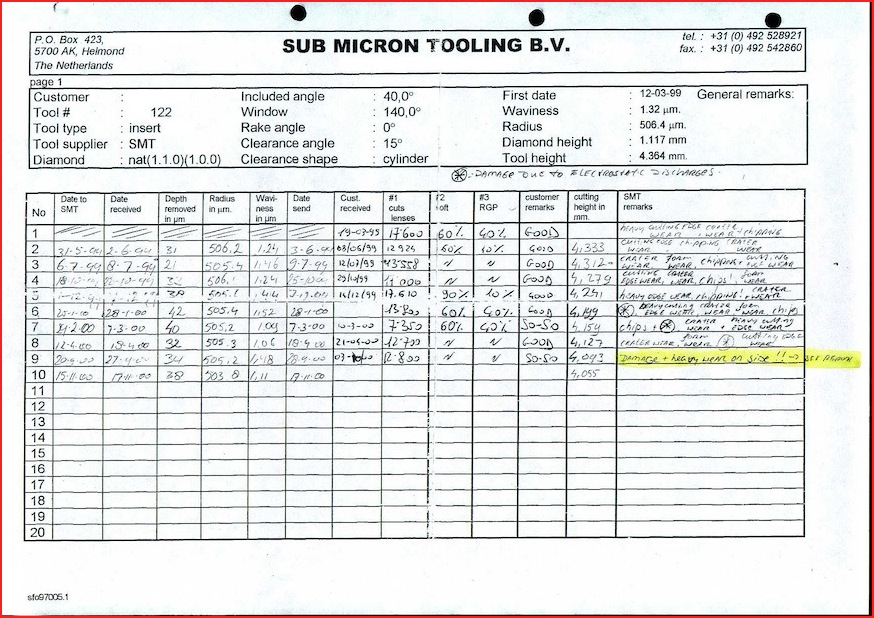

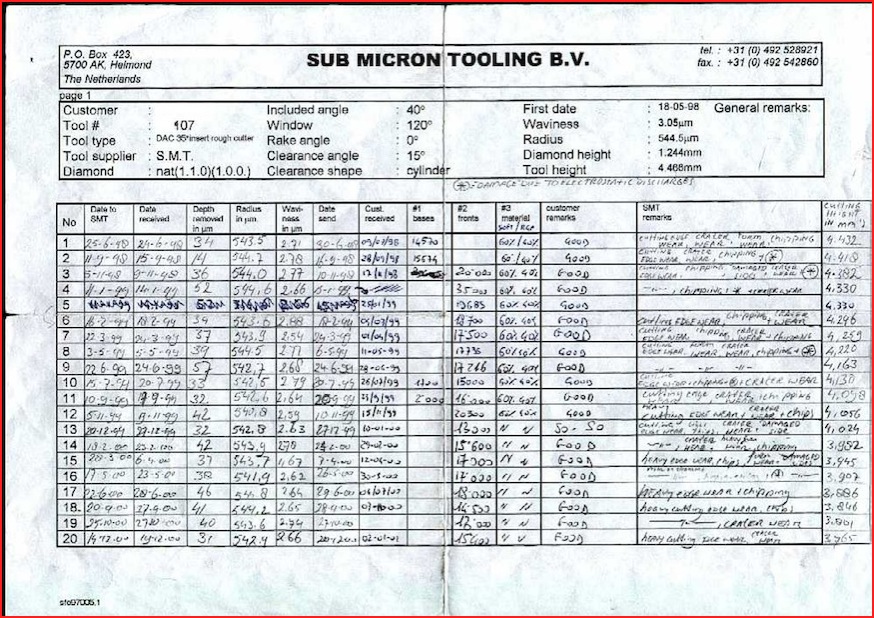

- Radius-size and waviness of the tool are measured. This information is put on the tool record, including other useful information such as depth removed, cutting height, etc.

- Customer receives a confirmation that the order is ready for shipment.

- The tools, together with the tool records and inspection reports, are being returned to the customer.

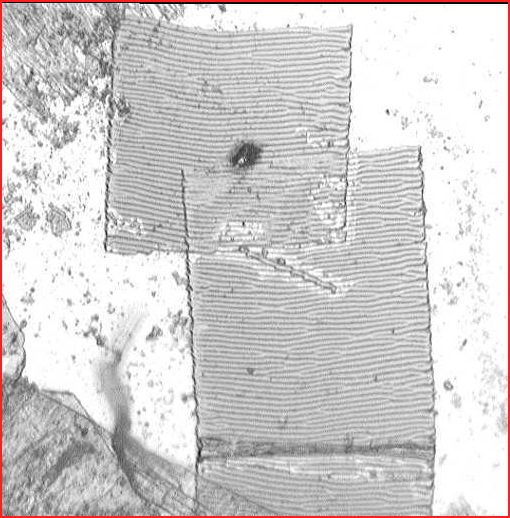

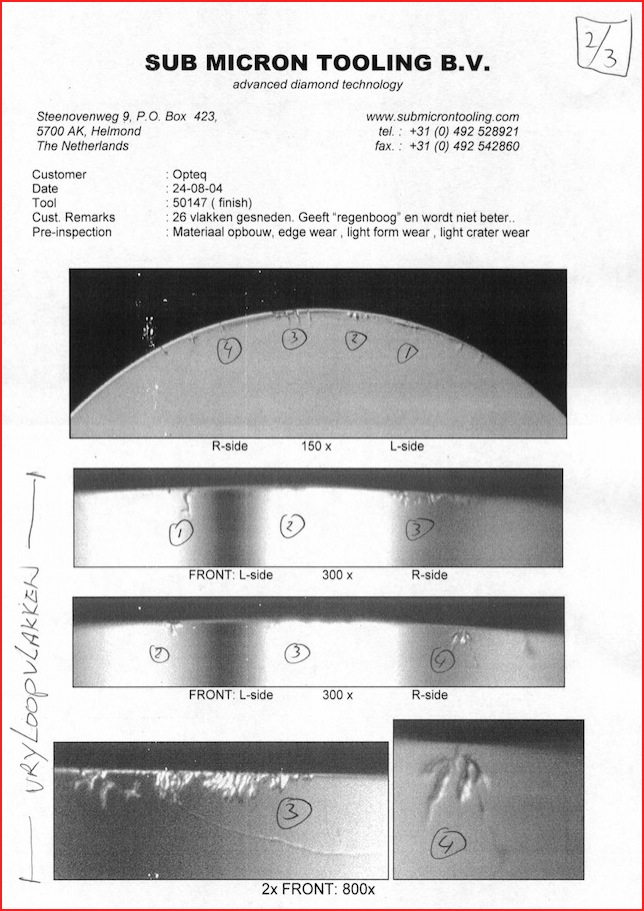

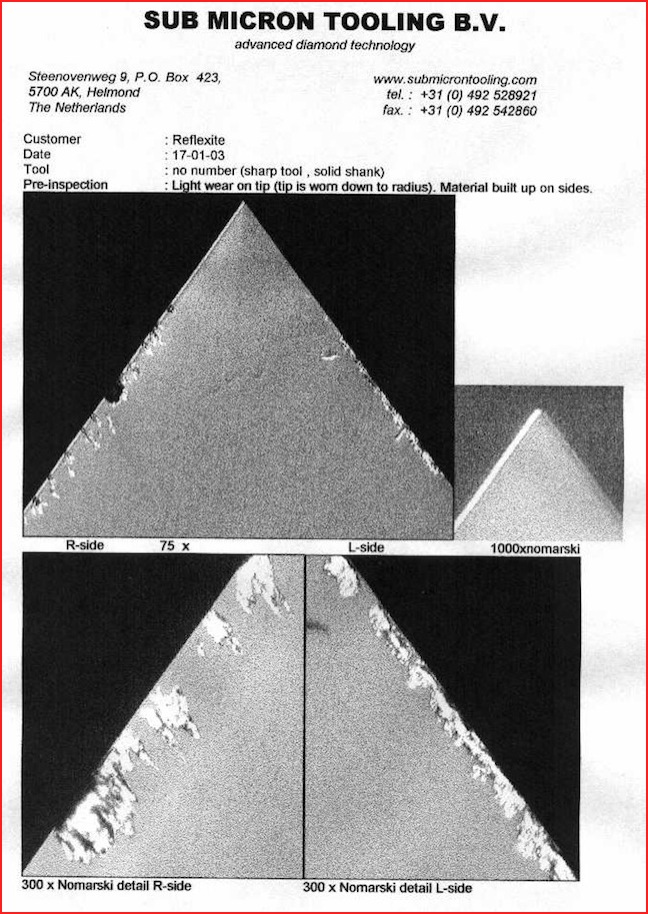

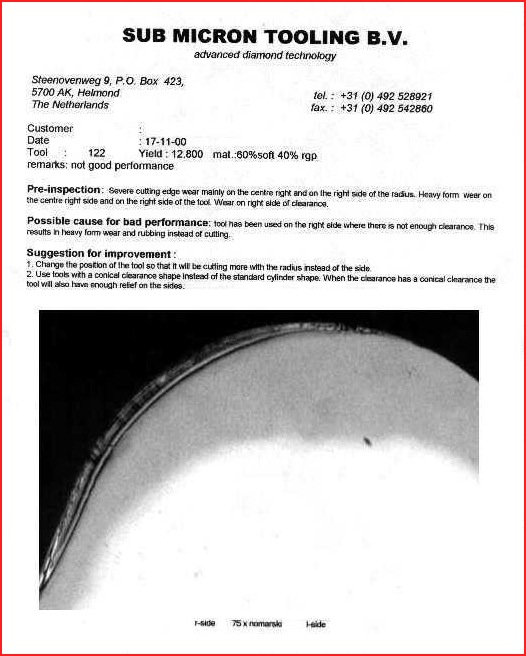

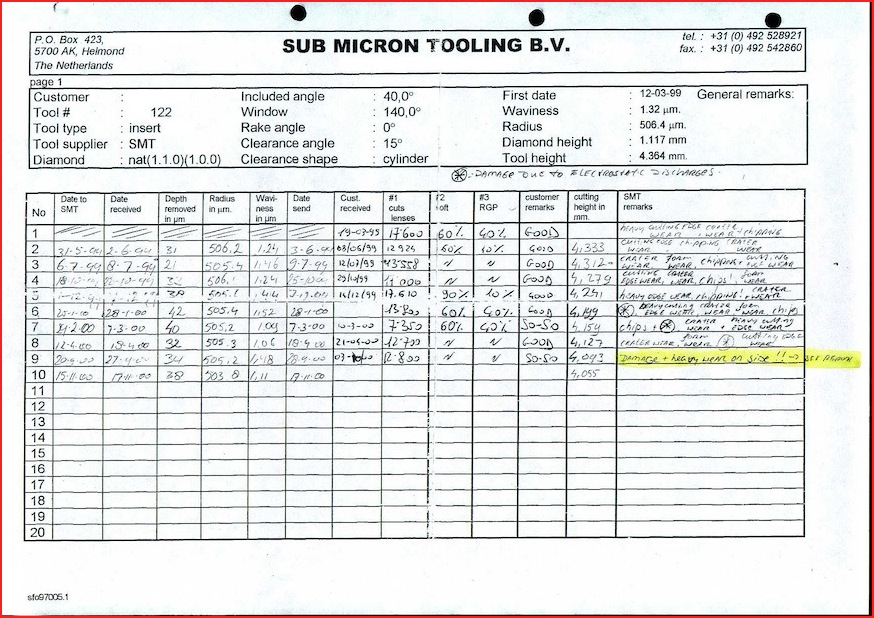

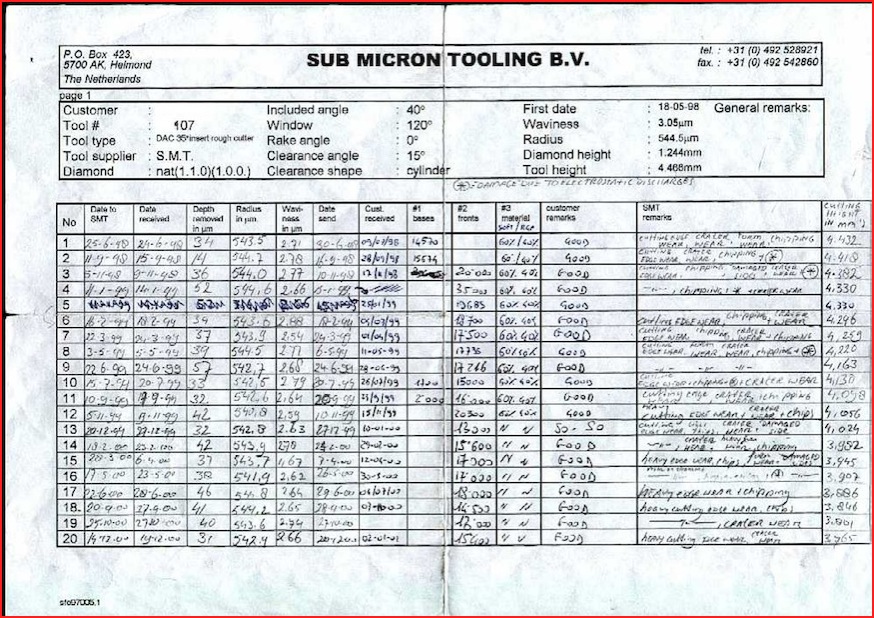

Examples of used tool records

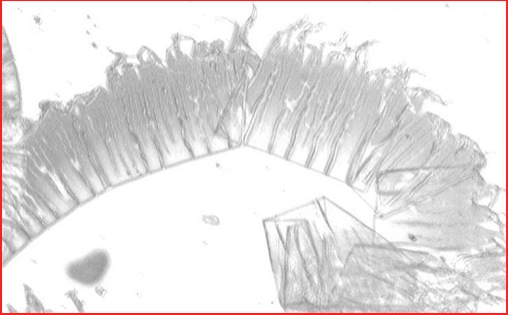

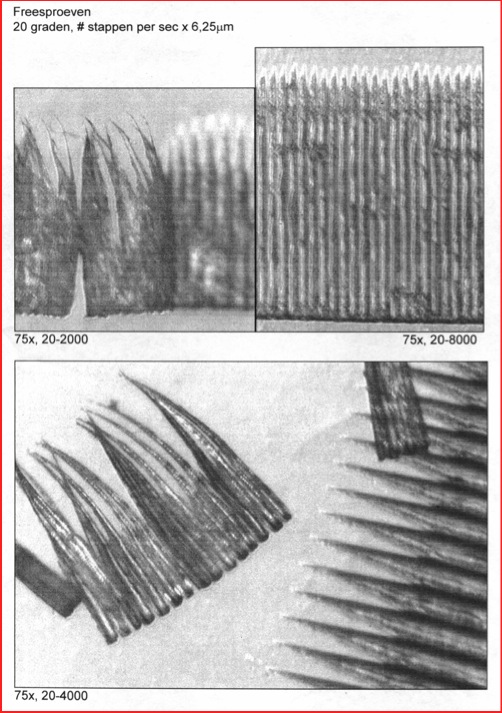

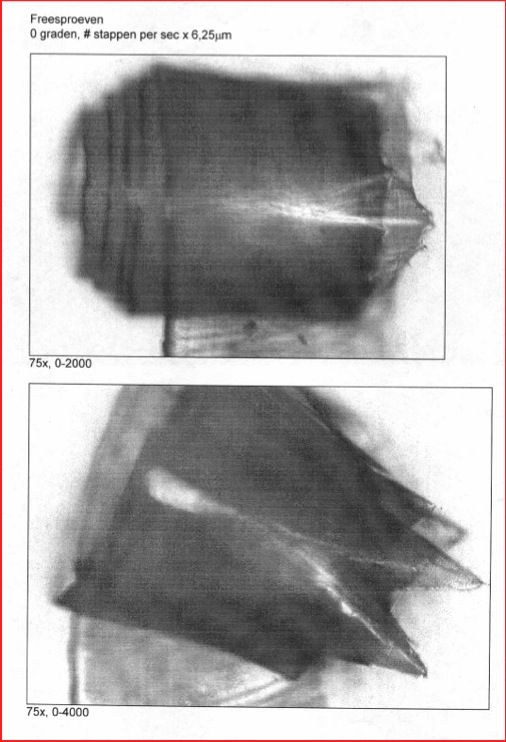

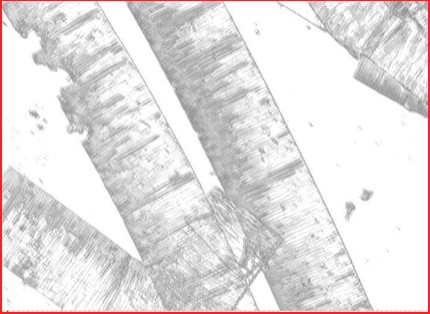

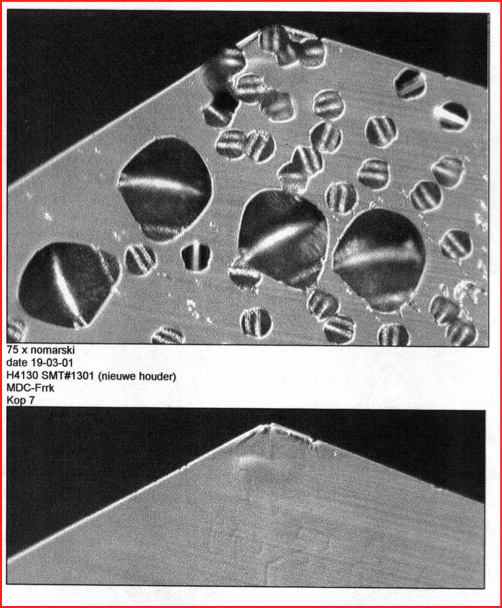

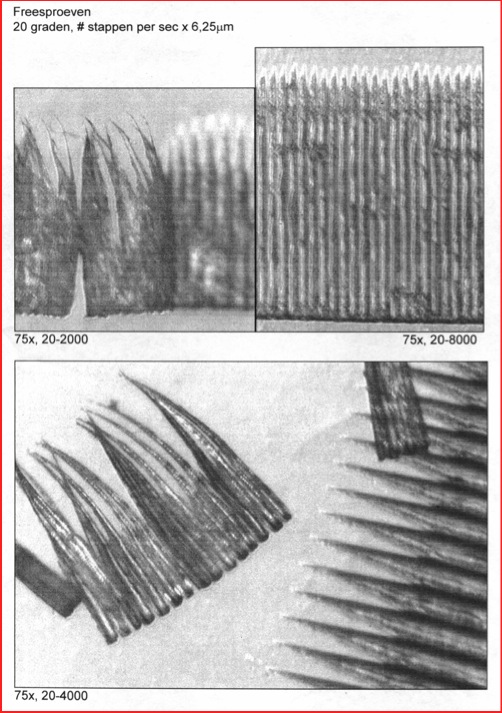

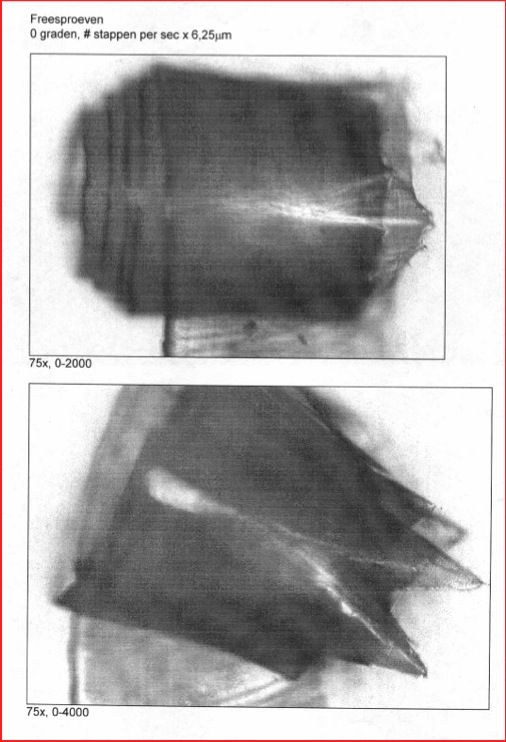

Swarf

Studying the wear patterns on the tool and/or the swarfs (chips) contributes to the analysis of the tool performance. This is important of the further optimalization.

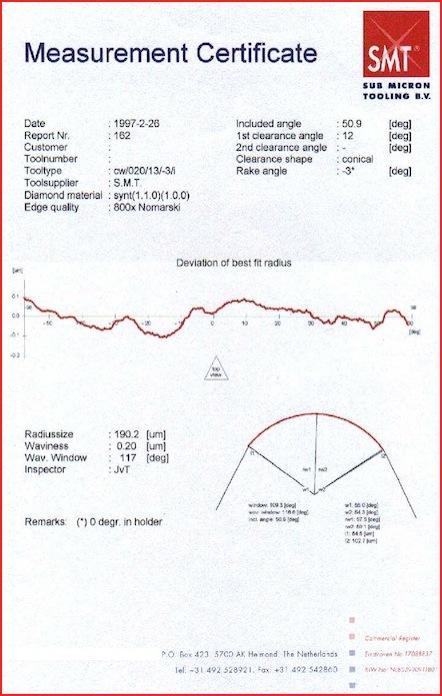

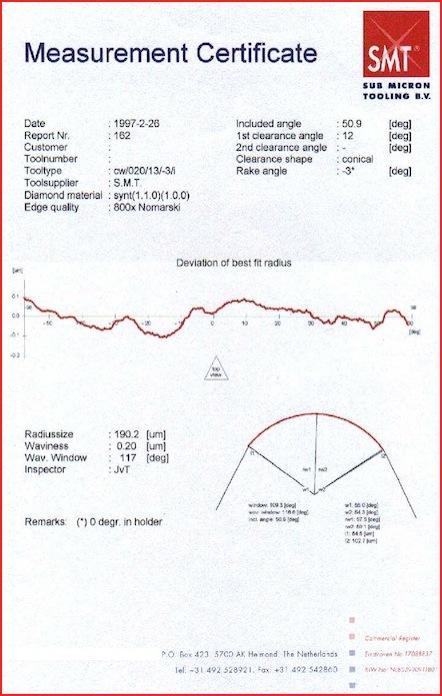

What is a certificate?

A certificate is a graphical display of the cutting edge. By an optical measurement, it is giving the radius size and the related form accuracy, including related angles.

Why a certificate?

Supplied with new tools, the measurement indicates that the required specifications

and tolerances are according to the

customer demands.

For relaps, the measurement is used as an instrument to analyse wear and form wear

of the used cutting edge (before the

relap is actually made).

See more at our Tool Management program.

Relapping tools

The purpose of a relap is to enable the tool to be used as new again, by

creating a

new sharp cutting edge. Other

definitions found for the term relapping are such as re-sharpen, re-grind,

repair,

re-polish, re-cut...

While a tool is used the cutting edge will wear due to several dynamics. At a

certain point, the cutting edge is

becoming too blunt or worn out for doing its cutting job. This is when you

decide to

take out the diamond and sent it

for relap.

Example of a relap

Shown is a synthetic radius diamond, used on a 2-axis cutting lathe. It has cut approx. 16,000 RGP lenses. Visible is a severe cutting edge and form wear nicely spread over the entire radius, which is mostly typical 2-axis use.

By grinding off diamond material from the table side, the wear will be disappeared on both table and clearance once enough is taken off. This means that a clean table and clearance shape have become the cutting edge. The wear-gallery is giving examples of wear on the clearance.

As a new cutting edge is formed, some tool parameters might have changed. For

those

applications where the exact

properties need to be known, the radius size and the waviness will be measured.

This

new data, including the amount of

diamond taken off and the wear detected, will be noted on the Tool Record. Also,

just like with new tools, a current

Measurement Certificate can be made of the relapped tool, displaying the

waviness

characteristics more in detail.

When the tool is properly used, a relap can be done several times using the same

tool. The amount of relaps per tool

depends however on the application, the machine used, the material cut, the

cutting

strategy, the environmental

conditions, the geometry of the tool, and even sometimes the operator involved.

On average, a tool used for roughing purposes can be relapped 20-50 times. A

tool

used for finishing purposes can be

relapped 30-80 times. In combination with our Tool Management system, the usage

can

be extended up to over 100 times.

Tool Management

Sub Micron Tooling is specialised in diamond tooling and the repair (relap) of

diamond tools. Due to the importance a

tool can have, as being part of a production process, the performance of the

tool

can have great impact on the success

of the user. Hence, any optimalisation of a tool is recommendable and close

relation

is needed with the user. Sub Micron

Tooling is a world-wide operating company based in the south of the Netherlands.

Yet, a good communication with the user

of a tool is needed in order to continue evaluating the performance of a tool

and to

continue striving to optimise the

processes the tool is used for. For this, we developed "Tool Management®" in

1996, a

service that has some great

advantages over any conventional service.

To name some interesting benefits of Tool Management

Fast relax service

On a standard basis, tools will be relapped and shipped back within 48 hrs after receipt. This means that you will have fewer tools in circulation, thus less investments involved.

Consistent quality

All tools are inspected and measured before and after repair to guarantee that tools will work. All the important tool information such as radius size, waviness, wear patterns, cutting height, etc. will be updated after each relap and corresponded to you.

Longer tool life

Because we realise more relaps per tool, you will have to buy fewer new tools. All our new tools are designed for maximum diamond life.

Building up knowledge

As we analyse and inspect each tool on its wear, causes may be found and

therewith

learning know-how. This will be

reported to you for each tool.

After the aforementioned benefits and promises, we would like to explain how we

keep

them. Therefore we add in more

detail what "Tool Management" is about.

"Tool Management makes it possible to optimise the use of diamond tools".

By using diamond tools, wear and damage will develop. This wear and damage is

related

to a great variety of factors,

such as the tool geometry, the lathe being used, the material cut, the product

being

made, the cutting parameters

(speed, feed), the operator, environmental conditions, etc. etc. So, by looking

at

the wear and damage we are able to

obtain information about the cutting processes at the customer and their quality

needs. By obtaining this information we

are gaining knowledge about the customer, from which the customer benefits. On

base

of our knowledge on diamond tools in

general, applications, lathes, cutting strategies, customer related knowledge

and

the quality needs of the individual

customers we can give advise, come up with solutions and improve processes.

The above approach, together with a fast relap service, maximum diamond life,

tool

trace ability, state of the art

technology and very competing prices will give you, our customer, the

possibility to

optimise the use of your diamond

tools.

In short, the steps are as follows:

- Customer ships tool(s) to SMT by post or forwarding agent.

- Tools are being received by SMT and generally inspected. The customer receives a confirmation that tools are received, an expected delivery time and estimated price.

- Tools are individually inspected and the wear analysed. For each tool, a tool record is being made, and if possible and needed a pre-inspection report is being made. The waviness of the radius is being measured before the relap, as this may be an indication of the wear and the cutting process it is used for.

- On base of the pre-inspection and measurement, we decide how the tool will be relapped in order to take off a minimum of diamond height, obtain a maximum tool life and remove all wear and damage.

- The tool is relapped on specially designed relapping machines, which prevents stress in the diamond and lapping lines.

- After relap the tool is inspected and measured to make sure all wear and damage is removed.

- Radius-size and waviness of the tool are measured. This information is put on the tool record, including other useful information such as depth removed, cutting height, etc.

- Customer receives a confirmation that the order is ready for shipment.

- The tools, together with the tool records and inspection reports, are being returned to the customer.

Examples of used tool records

Swarf

Studying the wear patterns on the tool and/or the swarfs (chips) contributes to the analysis of the tool performance. This is important of the further optimalization.

What is a certificate?

A certificate is a graphical display of the cutting edge. By an optical measurement, it is giving the radius size and the related form accuracy, including related angles.

Why a certificate?

Supplied with new tools, the measurement indicates that the required

specifications

and tolerances are according to the

customer demands.

For relaps, the measurement is used as an instrument to analyse wear and form

wear

of the used cutting edge (before the

relap is actually made).

See more at our Tool Management program.